What are the AS9103 Rev. B Key Characteristics?

Buy the AS9103B Standard

9103B Definition:

AS9103 Rev B is a standard within the aerospace industry that focuses on Variation Management of Key Characteristics (KCs) in quality management systems.

AS9103 Rev B aims to improve manufacturing and maintenance processes by effectively managing Key Characteristics variation, leading to uniformity and higher acceptance probability of end-products.

Scope of 9103 Rev. B

- AS9103B primarily applies to new parts and products intended for ongoing production. However, it can also be used for parts currently in production (e.g., manufacturing, maintenance).

- It covers all production processes that influence Key Characteristics variation, including maintenance and service processes where Key Characteristics are identified.

- The standard is relevant to assemblies and all levels of parts, down to basic materials like castings and forgings.

- It ensures that the design characteristics of the product are produced consistently.

Managing Variation in Key Characteristics (AAQG)

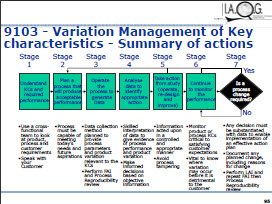

IAQG has an excellent Key Characteristics Presentation, listed here for your convenience:

The presentation outlines the seven stages process for Key Characteristics

Variation Control Process:

- The process begins with product definition, typically stated in design documentation (e.g., digital models, engineering drawings, specifications).

- It identifies KCs and leads to a variation management process for those KCs.

- This process may also apply to producer-identified KCs (e.g., process KCs, additional/substitute product KCs).

More Info:

- AAQG Key Characteristic Variation Presentation

- SAE AS9017 Control of Aviation Critical Safety Items (CSI) may apply

- AS9017-requirements for CSI management for organizations and suppliers who perform work for prime contractors receiving direct contracts from U.S. government agencies. (1st Tier or Prime suppliers)

- AS9107 is auditable with the expectation that the prime contractor will flow CSI requirements to the supply chain and periodically assess, audit, validate, and recognize compliance to AS9017 per their own processes.